Hot Melt Adhesive Film Manufacturer in China

Hengning is your trusted hot melt adhesive film supplier. We provide hot melt adhesive film of different types and materials.

- Free samples of different thicknesses and width

- Environmentally friendly and pollution-free

- High viscosity and high elasticity

- Wide range of applications

What is hot melt adhesive film?

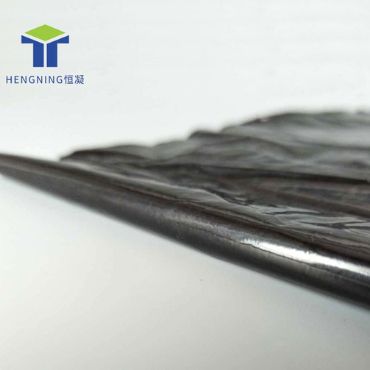

Hot melt adhesive film is made of plastic. It is non-toxic tasteless, and environment friendly. Hot melt adhesive film looks like normal plastic films at room temperature and will melt and be sticky at a temperature above the melting point. With a certain amount of pressure and time, it can bond two materials together.

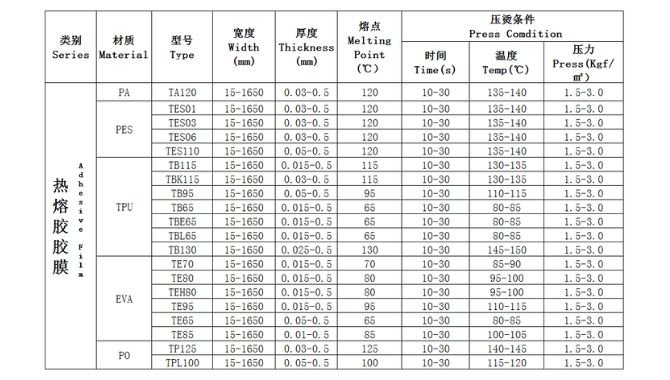

Hot Melt Adhesive Film Series

TPU is a thermoplastic polyurethane with good elasticity and washable properties. Suitable for clothing shoe material and other fields. With or without release paper, high melting point or low melting point for your choice.

PA is polyamide material, mostly with release paper. Has good low-temperature resistance and washing resistance. It has a good bonding effect. It can be used for bonding fabric, leather, PVC, and other materials. The different melting points for your choice.

PES is polyester. It has a wide bonding range and good washing resistance. We can provide different melting points and thicknesses. Widely used in clothing, electrical appliances, electronics, shoe-making, construction, and other industries.

The product has the characteristics of fast curing and strong adhesion. It is an environmentally friendly and efficient industrial adhesive. Widely used in the shoe industry, automobile industry, wallcovering manufacturing, and other industries.

PO is also called EAA. You can customize the thickness and width of the product. It has good low-temperature resistance of high-temperature resistance. The product has a very good bonding effect on metal, plastic, wood, and other materials.

Hot Melt Adhesive Film by Functions (5)

Hot Melt Adhesive Film by Bonding Materials (4)

Hengning Hot Melt Adhesive Film Advantages

Hot melt adhesive film products of Hengning have passed the SGS environmental protection certification, with no pollution to the environment.

Hot melt adhesive film products are non-toxic and tasteless, It’s very safe for the human body. It is a kind of environmental protection adhesive product.

You can customize the width and thickness according to your needs. You can also customize the packaging of hot melt adhesive film.

Our products have passed many certifications. And we have strict enterprise internal control standards, each shipment will carry out product quality testing.

Hengning Hot Melt Adhesive Film

Our hot melt adhesive film is available in 5 different materials with customizable thickness and width. There are lots of different materials with different melting points for your choice.

Hengning Production of Hot Melt Adhesive Film

Hengning is a professional hot melt adhesive series manufacturer and supplier in China. We are devoted to the research and development, production, and sales of hot melt adhesive products, Our products are of complete types and models and have been serving the global market for a long time. We have experienced engineers who can precisely control the production process with advanced production equipment. Our products are widely used in many industries, such as clothing, bags, cars, shoes, medical, electronics, and other industries. And we have customers in almost all industries, which makes us more professional than the competitors in the market.

Customization and R&D by Hengning

Hengning support customized service. You can customize the thickness, width, and packaging of hot melt adhesive film products. When our products can not meet your needs, we have a professional R & D team, that can develop new products according to your requirement. If you have customization and R&D needs, please feel free to contact me.

Choose Hengning To Produce Your Hot Melt Adhesive Film

We pursue to meet the needs of customers in all aspects, fully implement the enterprise purpose of “quality first, reputation first, service first”, strives to provide customers with the best quality and best products, treats every customer with professional service quality, gradually builds a benchmark enterprise in the industry, and gradually opens up the domestic and oversea market, so that products circulate throughout the whole world.

Send us a message right now!

Hengning Hot Melt Adhesive Film

Hot melt adhesive film products with release paper can first bond one side to the material that needs to be compounded, and then peel off the release paper. Finally, Give it a certain amount of time, pressure, temperature, and bond it whit the other side film with release paper is widely used in embroidery armbands, wall cloth, and other fields.

Hot melt adhesive film without release paper can be directly melted for bonding use. In order to reduce the cost hot melt adhesive film without release paper was born. More efficient production equipment has been adopted. It is widely used in the shoe industry, automobile industry, and composite field of building materials.

Hot Melt Adhesive Film Applications

The shoe manufacturing process is complex, and the upper material involves a wide variety of types, involving leather, artificial leather, fabric, etc., involving a variety of models of hot melt adhesive film.

EVA hot melt adhesive film or TPU hot melt adhesive film is often used for the lamination of insoles, depending on the material of the insole to be bonded.

Automotive seats usually involve the lamination of leather, leather, fabric, sponge, and other materials, and have relatively high requirements for the bonding strength of the materials after lamination.

In the clothing field, we have different products for the composite of different materials. Seamless boat socks, underwear, and panties need to use hot melt adhesive film products with high elasticity and water resistance.

For embroidery armbands, most use hot melt film with release paper. It can first bond one side to the material that needs to be compounded and then peel off the release paper. And then bonded to another layer of material.

Why Hengning is Trusted By Over 1000 Global Clients

- Company Strength

- Product Details

Related Product

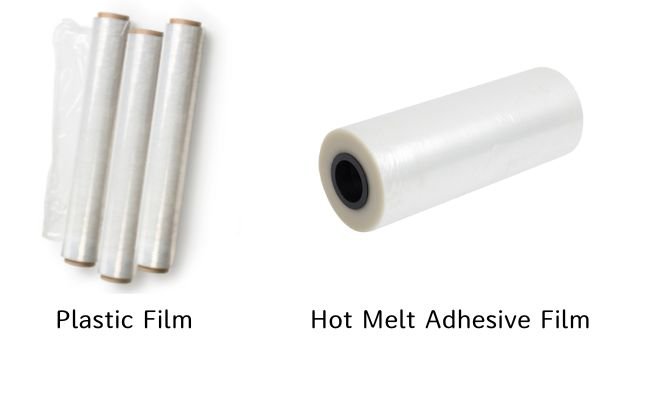

Ordinary plastic film and hot melt adhesive film look very similar on the surface, but their product construction and use are completely different.

Ordinary plastic film is not sticky, our life is very common, such as plastic film, greenhouse film, winding film, and so on.

Hot melt adhesive film is a plastic adhesive that can be used to bond different materials. All kinds of cloth, metal, etc.

- Hot melt adhesive film has strong adhesion, is non-toxic and tasteless, very environmental protection.

- Many kinds of hot melt adhesive film can meet the application needs of different products.

- Hot melt adhesive film bonding speed, simple operation, save manpower, significantly improves production efficiency, and saves costs.

- More environmentally friendly than the traditional glue, and more conducive to the protection of the environment.

- The performance of hot melt film is excellent, with good waterproof and high-temperature resistance, and low-temperature resistance performance. Long-term use does not deform.

There are two forms of hot melt adhesive film, with release paper and without release paper, from the appearance is also easy to see the difference.

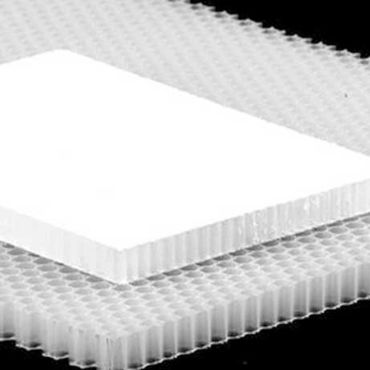

The hot melt adhesive film without release paper can be directly composite, put the hot melt adhesive film in the middle of two layers of material, and after a hot pressing, the two layers of material together.

Hot melt adhesive film with release paper can be first the composite side of the material, then torn off the release paper, and then composite another layer of material. The product needs hot pressing twice. Widely used in embroidery armbands and other fields.

First of all, we need to identify the material to be bonded. Different materials will have different hot melt adhesive film to match them.

Secondly, we need to consider the high-temperature resistance of the material, we have high temperature and low-temperature hot melt adhesive film, that can meet the requirements of most products, and you can find the most suitable temperature.

Thirdly, we should also consider the hand feel, some hot melt adhesive film feels hard, some soft.

In addition, there are many performance implications to consider. Such as the use of high temperature and low temperature, water washing resistance, dry cleaning resistance, elastic, and other factors.

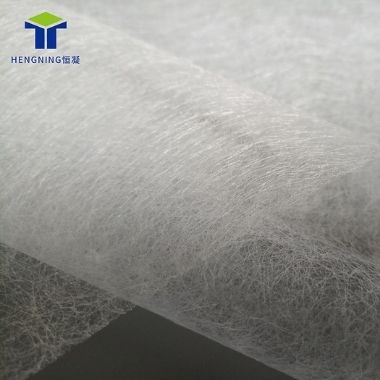

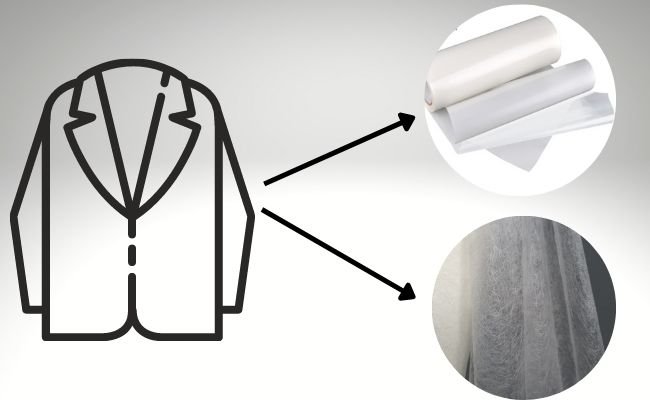

Hot melt adhesive film and hot melt adhesive web film can be used for clothing bonding, many people don’t know which material to use.

For stitching between fabrics, we use hot melt adhesive film, because the hot melt adhesive film is very uniform, and the bonding effect will be better.

For the compound between fabrics, hot melt adhesive web film is usually used. Because the area of this part is relatively large, the amount is also relatively large. In addition, when there are certain requirements for air permeability and softness, most of the hot melt adhesive web film is used.

Hot melt adhesive film will also be used in the field of seamless fitting, such as women’s seamless underwear, seamless socks, etc. For the field of seamless underwear, we often use a hot melt adhesive film with high elastic energy, belonging to TPU material, but more elastic than the ordinary TPU material of hot melt adhesive film.